John of Freight Dog Tales has left his box-hauling 'Van flying job and returned to freelance flight instructing, which can be a pretty good paying job for an experienced instructor like John (particularly given his expertise in the G1000, something not very many flight instructors outside of big schools have.) We'll miss his insights into the world of freight dogging, but John hasn't quit blogging; he's just moved to a new blog, Aviation Mentor. I think John's new blog will be an excellent way to explore the world of professional flight instruction (as opposed to timebuilding). It's an aviation career that too many up-and-coming pilots immediately dismiss.

As I told John: Once a freight dog, always a freight dog. Many of the captains I fly with were box haulers in their former lives, and when we get to telling flying stories, we don't tell airline stories - we tell Freight Dog Tales.

Sunday, May 28, 2006

The Envelope Please, Multimedia Update

I decided to just make a seperate post for the pics, audio, and video from my trip to The Hague.

I took quite a few video clips with my digicam, and am posting three here via MegaUpload. They're about as low quality as you'd expect from a point-and-shoot digicam but still hopefully a little interesting.

The first clip is from the train ride between Schipol Airport and Den Haag as the Dutch countryside abruptly changes to suburbs. Highlights include cows & a windmill.

The other two clips are from the concert/party at ASTA. The first was taken from just behind the DJ booth, watching Mr. Jonas Steur manning the decks. The second was taken from the main floor during the end of Armin van Buuren's set. The crowd is going nuts!

The entire nine hour event was broadcast live on various FM stations and internet streams around the world. I've uploaded two mp3s (again, MegaUpload) from Armin van Buuren's two hour set that give a very good flavor of the atmosphere and energy in the crowd.

"Arisen" by Arksun was the very first track in Armin's set. Armin played his own remix of Racoon's "Love You More" about halfway through his set.

And finally, some pictures from the trip:

I took quite a few video clips with my digicam, and am posting three here via MegaUpload. They're about as low quality as you'd expect from a point-and-shoot digicam but still hopefully a little interesting.

The first clip is from the train ride between Schipol Airport and Den Haag as the Dutch countryside abruptly changes to suburbs. Highlights include cows & a windmill.

The other two clips are from the concert/party at ASTA. The first was taken from just behind the DJ booth, watching Mr. Jonas Steur manning the decks. The second was taken from the main floor during the end of Armin van Buuren's set. The crowd is going nuts!

The entire nine hour event was broadcast live on various FM stations and internet streams around the world. I've uploaded two mp3s (again, MegaUpload) from Armin van Buuren's two hour set that give a very good flavor of the atmosphere and energy in the crowd.

"Arisen" by Arksun was the very first track in Armin's set. Armin played his own remix of Racoon's "Love You More" about halfway through his set.

And finally, some pictures from the trip:

Saturday, May 27, 2006

The Envelope, Please

Ladies and Gentlemen, the 2006 Insane Jumpseater of the Year Award goes to... me! I think Dawn gets to share the award, as she encouraged me to embark on this little adventure...

After my trip ended on Wednesday, I hopped on a Northwest flight to MSP, where I caught another NWA flight to Amsterdam. It was delayed four hours for a flap problem, so we didn't land until 1630 central european time. That left just enough time to change, take the train to The Hague, eat, and go to ASTA nightclub for the 250th episode celebration of A State of Trance, a weekly music radio show produced by dutch DJ Armin van Buuren. The party lasted all night and featured sets by Jonas Steur, M.I.K.E., John Askew, Rank 1, Menno de Jong, and Armin van Buuren himself.

When the show ended at 0500 this morning, I walked to Den Haag Centraal Station to take the train to Schipol Airport...and discovered that all train service was suspended indefinately between Den Haag and Leiden due to an electrical problem. Whoops. I took a bus to Leiden instead and then caught the train to the airport, where I took Northwest to MSP. From there I took United to Denver and then Portland, arriving back here at 1900 PDT.

Three days...24 hours of flying...11,000 nm. Not that I'm bragging or anything [grin]. I'm going to bed now, as I haven't slept in a bed since tuesday night....

After my trip ended on Wednesday, I hopped on a Northwest flight to MSP, where I caught another NWA flight to Amsterdam. It was delayed four hours for a flap problem, so we didn't land until 1630 central european time. That left just enough time to change, take the train to The Hague, eat, and go to ASTA nightclub for the 250th episode celebration of A State of Trance, a weekly music radio show produced by dutch DJ Armin van Buuren. The party lasted all night and featured sets by Jonas Steur, M.I.K.E., John Askew, Rank 1, Menno de Jong, and Armin van Buuren himself.

When the show ended at 0500 this morning, I walked to Den Haag Centraal Station to take the train to Schipol Airport...and discovered that all train service was suspended indefinately between Den Haag and Leiden due to an electrical problem. Whoops. I took a bus to Leiden instead and then caught the train to the airport, where I took Northwest to MSP. From there I took United to Denver and then Portland, arriving back here at 1900 PDT.

Three days...24 hours of flying...11,000 nm. Not that I'm bragging or anything [grin]. I'm going to bed now, as I haven't slept in a bed since tuesday night....

Monday, May 22, 2006

How to Pass Time on a Maintenance Delay: Suggestion #132

1) Take an iPod, iPod Nano, or other digital jukebox of choice, and tape the earbuds to the boom microphone of your headset.

2) Select the transmit switch on your ARCDU to "PA," and press the "PA" button.

3) Use tape to hold the push-to-talk switch in the "transmit" position.

4) ROCK OUT!!! Set the volume knob to "11" and turn your mundane maintenance delay into a two hour festival of headbanging, air guitar playing, lipsyncing, regrettable disco moves, and maybe even a polka or two.

Note: It is suggested that you disassemble the above sound system before the aircraft is approached by any VP, chief pilot, or check airman.

2) Select the transmit switch on your ARCDU to "PA," and press the "PA" button.

3) Use tape to hold the push-to-talk switch in the "transmit" position.

4) ROCK OUT!!! Set the volume knob to "11" and turn your mundane maintenance delay into a two hour festival of headbanging, air guitar playing, lipsyncing, regrettable disco moves, and maybe even a polka or two.

Note: It is suggested that you disassemble the above sound system before the aircraft is approached by any VP, chief pilot, or check airman.

Saturday, May 20, 2006

A Weird Day

We started today in Helena, MT. It was supposed to be a fairly easy day with a scheduled 1610 departure to Seattle followed by a Missoula turn and then a Seattle-Edmonton flight arriving at midnight. Things didn't quite go as planned - for any of the legs.

On my preflight in Helena I discovered that one of the propeller blades had a substantial piece of its anti-ice heater element missing, with the rest starting to peel off. It's a common problem on the Megawhacker, but it usually gets written up before it gets that bad. Maintenance control called out contract maintenance; they used a knife to clean up the peeling part of the element and then consulted with our engineering department to determine if the airplane was airworthy. Eventually they decided it wasn't, and the airplane would need to be ferried to a maintenance base for repair. The HLN-SEA revenue flight had to be cancelled.

Seattle was be the most logical maintenance base, since the next flight for both airplane and crew was SEA-MSO. However, the ferry permit required us to stay out of icing conditions, and there was a fair amount of high level moisture between us and Seattle, so dispatch decided to send us to Boise instead. The Missoula roundtrip was cancelled, so our new goal was to make it to Seattle in time for the Edmonton flight. The Helena-Boise flight was fairly uneventful and interesting thanks to some scenery we don't normally fly over.

The repairs in Boise took about an hour; our next flight to Seattle would be an empty repositioning leg. We had just lifted off and retracted the landing gear when something interesting happened: The gear doors closed, and then opened, and then closed again. The captain and I did a doubletake and eyed the gear lights skeptically; then the doors cycled again, this time with a gear unsafe indication which lasted for a few seconds. A few seconds after that, the left gear door cycled again. By now it was clear that something was not right, so I kept the airplane slow while the captain called maintenance on the radio. The landing gear ceased its antics then, so I accelerated to normal cruise climb speed and maintenance control decided not to have us return to Boise, but divert us to Portland. We got our dispatcher to rerelease us and got a new clearance from air traffic control.

There were quite a few buildups and we were getting into IMC so I turned the radar on; true to form, it refused to operate. I tried turning it on and off a few times, to no avail. Suddenly, it started to paint a return...but it wasn't green or yellow or red or pink...it was blue!!! Neither of us had any idea that the radar was capable of displaying blue. And it wasn't a regular weather return, it was a blob that grew with every sweep of the radar until it filled the screen. We looked at each other in disbelief; I remarked that I was thinking this airplane was possessed. When we looked back, the radar was painting weather echoes with its usual color palette.

We began our descent into Portland while still east of the Cascades, and started picking up some light rime ice. Suddenly, the autopilot disconnected, the PFD displayed a flashing "IAS mismatch" warning, and several caution lights came on, including "pitch trim," "elevator feel," "rudder control," and "outboard spoilers." I handflew the airplane while the captain ran the appropriate checklist. I noticed that the captain's PFD was indicating significantly less airspeed than my own, and it was decreasing as we descended. My own airspeed was the same as the standby airspeed indicator, so I was pretty sure the captain's airspeed was wrong. Given all the gremlins on this flight, I was getting a little creeped out.

A tidbit from long-ago instrument training came to mind: "A blocked pitot tube will cause an airspeed indicator to behave as an altimeter." Suddenly I realized what had happened: the captain's airspeed indicator, presumably blocked by ice, had caused the #1 air data computer to take itself offline, resulting in the various caution lights. The checklist confirmed my suspicions and directed us to switch captain-side instruments to ADC2. Before we did so, his airspeed returned to normal and all caution lights extinguised. We continued at a reduced airspeed and I handflew the rest of the way, just to be safe, but the problem never came back. I'm guessing it melted away.

After all this, we were more than happy to part with Aircraft 416. We weren't sure that we'd be flying anymore, given how short the company was on planes today. However, we had cancelled three flights already and dispatch wasn't about to hear of a fourth! After we parked 416 at the hangar in PDX, we hurried over to aircraft 407, newly repaired after an air conditioning writeup. We flew it empty to Seattle - our third repositioning flight of the day - and quickly loaded the Edmonton passengers onboard. We departed about 1.5 hours late.

The day wasn't quite done with us, though. As we approached Edmonton, we were treated to a brilliant lightning display from storms on the east, north, and west sides of the airport. The strong gusty winds were favoring runway 12; we kept our base in tight to stay as far as possible from a strong cell just to the west. As I passed through 500' on a classic "black hole approach" to a runway with an inop glideslope and VASI, flying "solid blue bug" for windshear preparation, I realized that there were places I'd much rather be at 1:30 am on a stormy night. Oh well. The landing was passable if not silky smooth.

Tomorrow is only one leg to Seattle, then a deadhead to Portland. One leg. That should be simple enough to not screw up, right? After today, I'm wondering....

On my preflight in Helena I discovered that one of the propeller blades had a substantial piece of its anti-ice heater element missing, with the rest starting to peel off. It's a common problem on the Megawhacker, but it usually gets written up before it gets that bad. Maintenance control called out contract maintenance; they used a knife to clean up the peeling part of the element and then consulted with our engineering department to determine if the airplane was airworthy. Eventually they decided it wasn't, and the airplane would need to be ferried to a maintenance base for repair. The HLN-SEA revenue flight had to be cancelled.

Seattle was be the most logical maintenance base, since the next flight for both airplane and crew was SEA-MSO. However, the ferry permit required us to stay out of icing conditions, and there was a fair amount of high level moisture between us and Seattle, so dispatch decided to send us to Boise instead. The Missoula roundtrip was cancelled, so our new goal was to make it to Seattle in time for the Edmonton flight. The Helena-Boise flight was fairly uneventful and interesting thanks to some scenery we don't normally fly over.

The repairs in Boise took about an hour; our next flight to Seattle would be an empty repositioning leg. We had just lifted off and retracted the landing gear when something interesting happened: The gear doors closed, and then opened, and then closed again. The captain and I did a doubletake and eyed the gear lights skeptically; then the doors cycled again, this time with a gear unsafe indication which lasted for a few seconds. A few seconds after that, the left gear door cycled again. By now it was clear that something was not right, so I kept the airplane slow while the captain called maintenance on the radio. The landing gear ceased its antics then, so I accelerated to normal cruise climb speed and maintenance control decided not to have us return to Boise, but divert us to Portland. We got our dispatcher to rerelease us and got a new clearance from air traffic control.

There were quite a few buildups and we were getting into IMC so I turned the radar on; true to form, it refused to operate. I tried turning it on and off a few times, to no avail. Suddenly, it started to paint a return...but it wasn't green or yellow or red or pink...it was blue!!! Neither of us had any idea that the radar was capable of displaying blue. And it wasn't a regular weather return, it was a blob that grew with every sweep of the radar until it filled the screen. We looked at each other in disbelief; I remarked that I was thinking this airplane was possessed. When we looked back, the radar was painting weather echoes with its usual color palette.

We began our descent into Portland while still east of the Cascades, and started picking up some light rime ice. Suddenly, the autopilot disconnected, the PFD displayed a flashing "IAS mismatch" warning, and several caution lights came on, including "pitch trim," "elevator feel," "rudder control," and "outboard spoilers." I handflew the airplane while the captain ran the appropriate checklist. I noticed that the captain's PFD was indicating significantly less airspeed than my own, and it was decreasing as we descended. My own airspeed was the same as the standby airspeed indicator, so I was pretty sure the captain's airspeed was wrong. Given all the gremlins on this flight, I was getting a little creeped out.

A tidbit from long-ago instrument training came to mind: "A blocked pitot tube will cause an airspeed indicator to behave as an altimeter." Suddenly I realized what had happened: the captain's airspeed indicator, presumably blocked by ice, had caused the #1 air data computer to take itself offline, resulting in the various caution lights. The checklist confirmed my suspicions and directed us to switch captain-side instruments to ADC2. Before we did so, his airspeed returned to normal and all caution lights extinguised. We continued at a reduced airspeed and I handflew the rest of the way, just to be safe, but the problem never came back. I'm guessing it melted away.

After all this, we were more than happy to part with Aircraft 416. We weren't sure that we'd be flying anymore, given how short the company was on planes today. However, we had cancelled three flights already and dispatch wasn't about to hear of a fourth! After we parked 416 at the hangar in PDX, we hurried over to aircraft 407, newly repaired after an air conditioning writeup. We flew it empty to Seattle - our third repositioning flight of the day - and quickly loaded the Edmonton passengers onboard. We departed about 1.5 hours late.

The day wasn't quite done with us, though. As we approached Edmonton, we were treated to a brilliant lightning display from storms on the east, north, and west sides of the airport. The strong gusty winds were favoring runway 12; we kept our base in tight to stay as far as possible from a strong cell just to the west. As I passed through 500' on a classic "black hole approach" to a runway with an inop glideslope and VASI, flying "solid blue bug" for windshear preparation, I realized that there were places I'd much rather be at 1:30 am on a stormy night. Oh well. The landing was passable if not silky smooth.

Tomorrow is only one leg to Seattle, then a deadhead to Portland. One leg. That should be simple enough to not screw up, right? After today, I'm wondering....

Tuesday, May 16, 2006

A Tale of Two Trails

Dawn and I had company this weekend (her mom and two college friends) which provided the perfect excuse to get out and do some hiking. We took the out-of-towners on two rather different hikes, as seen below:

(First three pictures: Wahkeena Creek and Multnomah Creek/Multnomah Falls in the Columbia River Gorge. Last three pictures: Mt. St. Helens National Volcanic Monument.)

What's amazing to me is that these places are just two sides of the same geological coin. The only difference is that one place has had enough time since its last cataclysmic event to let water and wind sculpt it and revegetate it. From the air, you can sense this: other than the lack of vegetation, the area devastated by Mt. St. Helen's 1980 eruption is eerily similar to other parts of the Cascades quite close to large populations. Up close, though, it's a moonscape, an awesome testament to the unbridled power of a volcano that's not quite ready to go to sleep.

Take a look at the last picture of Mt. St. Helens' crater. Do you see the large spine of snowless rock that is steaming? That formation is new since September 2004. It is now 1500' high and continually growing. It's big enough to be seen from the air over 50 miles away. Scientists say that if this new lava dome continued to build at its current rate, the mountain would be back to its pre-1980 height within ten years. That's not even a blip in geological time.

The nearly continuous eruption of Mt. St. Helens over the past two years reminds us that the Juan de Fuca plate is still happily grinding away under the Pacific Plate, the same process that built the Cascades and blew away the north face of Mt. St. Helens. The Pacific Northwest has been rocked by "great earthquakes" (8.0+) every 300-800 years when this fault slips; it has now been 306 years since the Cascadia Earthquake (9.0!). Many other Cascades volcanoes are active; Mt Rainier is the most dangerous of these, as it has a history of sudden collapses which trigger massive lahars (destructive mudflows). Tacoma, Puyallup, and parts of Seattle were built on the remains of past lahars that occured every 500-1000 years with the last big lahar happening around 530 years ago. The mayor of Orting, WA, is actually a customer service agent at my airline; I suspect she lays awake at night pondering the fact that her town of 3760 folks could be destroyed by even moderate lahar activity.

All this makes the Pacific Northwest just that much more interesting of a place to live and fly. When you see the area from the air, the geological events you read about become very real, and not all that distant in the past. Of course, I try not to say any of this on the PA; I don't think the pax would enjoy my VFR tours of the Cascades nearly as much!

(First three pictures: Wahkeena Creek and Multnomah Creek/Multnomah Falls in the Columbia River Gorge. Last three pictures: Mt. St. Helens National Volcanic Monument.)

What's amazing to me is that these places are just two sides of the same geological coin. The only difference is that one place has had enough time since its last cataclysmic event to let water and wind sculpt it and revegetate it. From the air, you can sense this: other than the lack of vegetation, the area devastated by Mt. St. Helen's 1980 eruption is eerily similar to other parts of the Cascades quite close to large populations. Up close, though, it's a moonscape, an awesome testament to the unbridled power of a volcano that's not quite ready to go to sleep.

Take a look at the last picture of Mt. St. Helens' crater. Do you see the large spine of snowless rock that is steaming? That formation is new since September 2004. It is now 1500' high and continually growing. It's big enough to be seen from the air over 50 miles away. Scientists say that if this new lava dome continued to build at its current rate, the mountain would be back to its pre-1980 height within ten years. That's not even a blip in geological time.

The nearly continuous eruption of Mt. St. Helens over the past two years reminds us that the Juan de Fuca plate is still happily grinding away under the Pacific Plate, the same process that built the Cascades and blew away the north face of Mt. St. Helens. The Pacific Northwest has been rocked by "great earthquakes" (8.0+) every 300-800 years when this fault slips; it has now been 306 years since the Cascadia Earthquake (9.0!). Many other Cascades volcanoes are active; Mt Rainier is the most dangerous of these, as it has a history of sudden collapses which trigger massive lahars (destructive mudflows). Tacoma, Puyallup, and parts of Seattle were built on the remains of past lahars that occured every 500-1000 years with the last big lahar happening around 530 years ago. The mayor of Orting, WA, is actually a customer service agent at my airline; I suspect she lays awake at night pondering the fact that her town of 3760 folks could be destroyed by even moderate lahar activity.

All this makes the Pacific Northwest just that much more interesting of a place to live and fly. When you see the area from the air, the geological events you read about become very real, and not all that distant in the past. Of course, I try not to say any of this on the PA; I don't think the pax would enjoy my VFR tours of the Cascades nearly as much!

Sunday, May 14, 2006

Going Once, Going Twice...

Hey, anybody want my four day trip (trip 714) starting on 23 May? It has a 655 showtime with layovers in Butte, Kalispell, and Helena, with a nice early release time of 1149 on the 26th. I've been trying to drop it but crew scheduling is being pretty persistent in denying the trip drop due to insufficient reserve coverage. Mind you, we've been fairly fat on Megawhacker FO's lately, but just the 24th is supposedly low.

The only catch is that you have to be qualified as an FO in the Megawhacker at my company. If that's you and you've found yourself with lots of days off and not enough paycheck - let's talk!

Update: It all worked out. Somebody picked up the trip I was trying to get, and then offered to trade trips with me. Thanks, J.E.!

The only catch is that you have to be qualified as an FO in the Megawhacker at my company. If that's you and you've found yourself with lots of days off and not enough paycheck - let's talk!

Update: It all worked out. Somebody picked up the trip I was trying to get, and then offered to trade trips with me. Thanks, J.E.!

Friday, May 12, 2006

Losing One - Update

I just got an email from a fellow FO at my airline directing me to his podcast blog, Hotel Coffee. I've only listened to one episode, but they're really excellent...I have some catching up to do. Until now I wasn't aware that any of my airline's pilots were active bloggers, much less podcasters.

What makes the latest podcast (#33) particularly interesting is that Dan was the FO on the flight that recently lost an engine out of Redding, as described in my last post. This is his second engine failure in two years; funny that he was paired with the captain that's probably had more engine failures than any other person at my airline. He describes the event in detail - check it out.

What makes the latest podcast (#33) particularly interesting is that Dan was the FO on the flight that recently lost an engine out of Redding, as described in my last post. This is his second engine failure in two years; funny that he was paired with the captain that's probably had more engine failures than any other person at my airline. He describes the event in detail - check it out.

Wednesday, May 10, 2006

Losing One

The captain that I flew with last trip, Steve, is a rather unlucky fellow when it comes to keeping engines running. He has experienced six engine failures at this airline, and several others before working here (including a catastrophic crankshaft failure in a single-engine C206). His most recent engine failure happened on his last trip, on takeoff out of Redding. They had just lifted off and retracted the gear when there was a bang and the left engine shut down. It was a nice VFR day so they just kept the airplane in the pattern, ran the appropriate checklists, and landed. The engine will be sent back to Pratt & Whitney for a postmortem, but preliminary analysis suggests a problem with the accessory gearbox, which drives the fuel metering unit.

Engine failures are relatively rare, but they are the failure that pilots train for most often, since a poorly handled engine failure can easily lead to a fatal accident. In a single-engine airplane, engine failure is deadly serious. Losing the only engine just after takeoff, over mountains, or at night all rank among pilots' worst nightmares. An alarmingly high number of accidents involve stalling and spinning in after the engine quits, even over terrain suitable for an emergency landing. (Edit: mechanical engine failures are rare. Fuel starvation is appalingly common.)

You would think that engine failure would be more survivable in a twin engine aircraft, but the available data suggests this isn't so. An old joke among pilots is that the second engine is there to fly you to the scene of the accident. When the failure occurs shortly after takeoff, you have two problems: low airspeed and low altitude. At low airspeeds, it's tough to maintain control of a twin that has full power on one side and lots of drag from a windmilling prop on the other. The airplane will yaw and roll violently, and the pilot must immediately apply aggressive control movements to maintain control. A large number of engine failure accidents in twins are simply due to failure to maintain control. I suspect that the last time many light twin pilots practiced engine-out maneuvers was during their training for the multi rating.

Then you have the low altitude in an aircraft that may or may not want to climb. There is no requirement that light twins be able to climb on a single engine, and some of the lower powered airplanes have dismal single engine climb rates, particularly at high density altitudes or heavy weights. Even capable airplanes like the Piper Navajo or Beech Baron are quite vulnerable if the engine failure occurs in the time between liftoff and Vyse, or single-engine best rate of climb speed. There are cases where even the best pilot may not be able to save the day.

In an airliner, engine failure is still a big deal, but you have a lot more going for you. For starters, you will always have adequate single-engine climb performance. For each takeoff, we look at performance data that is specific to each runway and takes temperature, wind, and aircraft configuration into account. It will give us a maximum weight for takeoff that assures adequate performance in the "worse case scenario" - that is, an engine failure right at V1 (see below). So, assuming the performance data is accurate, we know that the airplane will climb so long as we follow the proper engine-out procedures. For this, we have the benefit of realistic simulation training, and the fact that the non-flying pilot can take care of checklists, radio calls, etc, while the flying pilot concentrates on maintaining control of the airplane.

Airliners don't have the same V speeds as light aircraft, such as Vx, Vxse, Vy, or Vyse. Instead we have V1, Vr, V2, and Vse. These are calculated for each takeoff and are based on considerations such as aircraft weight, configuration, and runway/weather conditions. They are defined as follows:

So... you're hurtling down the runway in a Megawhacker, and just as you reach V1 , the master warning goes ding ding ding and the airplane starts yawing massively. What do you do?

Obviously, the first priority is to keep the airplane under control. This will take considerable force on the rudder and ailerons. You want to keep the nose pointed right down the runway. Then, as you reach Vr, you rotate to 10 degrees pitch, which should give you a speed close to V2. By this time, the offending engine should have auto-feathered its propeller so you don't have so much drag on that side, and the remaining engine will "uptrim" to give you 10% more torque. Once the airplane is positively airborne, the pilot not flying retracts the landing gear, and the pilot flying adjusts pitch to maintain V2. You don't run any checklists yet, you just concentrate on keeping the airplane under control and climbing to acceleration height (usually 1000' above airport elevation).

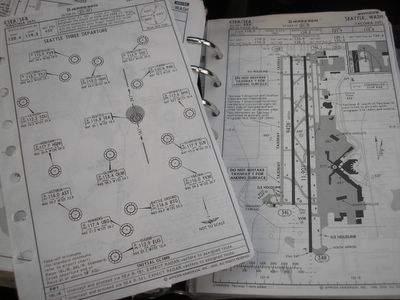

Each runway we use has a "turn procedure" assigned, to be used in the event of an engine failure. Many of these are rather simple and do not require a turn below acceleration height. Where obstacles present problems to slowly climbing aircraft, however, a complex turn procedure may be established. Most have textual descriptions, although a few are complex enough to require their own Jeppesen chart. Here's the turn procedure for runway 10L at Portland: "Climb via PDX radial 085 until reaching PDX DME 7.8, or IVDG DME 7.6, then turn right heading 280. Acceleration height 1030'." In this case, you'd make the turn to intercept the PDX 085 radial at 50 feet (!).

Upon reaching acceleration height, you level out, retract the flaps at V2 + 10 kts, and accelerate to Vse before resuming the climb at that airspeed. Only then does the pilot flying call for the engine failure checklist. This emergency checklist leads to several others ("engine failure cleanup items" and "single engine approach and landing"), which you'll do in between talking to ATC and your dispatcher (and possibly maintenance control), coordinating the arrival with your flight attendants, and perhaps making a PA to the passengers. Then it's time to land, smile at the passengers as they deplane, and go drink some beer.

Engine failures are relatively rare, but they are the failure that pilots train for most often, since a poorly handled engine failure can easily lead to a fatal accident. In a single-engine airplane, engine failure is deadly serious. Losing the only engine just after takeoff, over mountains, or at night all rank among pilots' worst nightmares. An alarmingly high number of accidents involve stalling and spinning in after the engine quits, even over terrain suitable for an emergency landing. (Edit: mechanical engine failures are rare. Fuel starvation is appalingly common.)

You would think that engine failure would be more survivable in a twin engine aircraft, but the available data suggests this isn't so. An old joke among pilots is that the second engine is there to fly you to the scene of the accident. When the failure occurs shortly after takeoff, you have two problems: low airspeed and low altitude. At low airspeeds, it's tough to maintain control of a twin that has full power on one side and lots of drag from a windmilling prop on the other. The airplane will yaw and roll violently, and the pilot must immediately apply aggressive control movements to maintain control. A large number of engine failure accidents in twins are simply due to failure to maintain control. I suspect that the last time many light twin pilots practiced engine-out maneuvers was during their training for the multi rating.

Then you have the low altitude in an aircraft that may or may not want to climb. There is no requirement that light twins be able to climb on a single engine, and some of the lower powered airplanes have dismal single engine climb rates, particularly at high density altitudes or heavy weights. Even capable airplanes like the Piper Navajo or Beech Baron are quite vulnerable if the engine failure occurs in the time between liftoff and Vyse, or single-engine best rate of climb speed. There are cases where even the best pilot may not be able to save the day.

In an airliner, engine failure is still a big deal, but you have a lot more going for you. For starters, you will always have adequate single-engine climb performance. For each takeoff, we look at performance data that is specific to each runway and takes temperature, wind, and aircraft configuration into account. It will give us a maximum weight for takeoff that assures adequate performance in the "worse case scenario" - that is, an engine failure right at V1 (see below). So, assuming the performance data is accurate, we know that the airplane will climb so long as we follow the proper engine-out procedures. For this, we have the benefit of realistic simulation training, and the fact that the non-flying pilot can take care of checklists, radio calls, etc, while the flying pilot concentrates on maintaining control of the airplane.

Airliners don't have the same V speeds as light aircraft, such as Vx, Vxse, Vy, or Vyse. Instead we have V1, Vr, V2, and Vse. These are calculated for each takeoff and are based on considerations such as aircraft weight, configuration, and runway/weather conditions. They are defined as follows:

- V1 is "Decision speed." If the engine failure occurs prior to V1, the captain will abort the takeoff. If the engine failure occurs at or after V1, you keep going. V1 is calculated for each takeoff to ensure balanced field length. This means that for an engine failure at V1, it will take the same distance to continue the takeoff as it will to abort. So by aborting prior to V1 or continuing after, you're choosing the option that'll take less distance.

- Vr is rotation speed, same as in a light plane.

- V2 is takeoff safety speed. In case of engine failure, you climb at this speed until acceleration height. It's analogous to Vxse (single engine best angle of climb) in a light twin.

- Vse is single engine climb speed. You would maintain this speed between acceleration height until level off. It's like Vyse (single engine best rate of climb) in a light twin.

So... you're hurtling down the runway in a Megawhacker, and just as you reach V1 , the master warning goes ding ding ding and the airplane starts yawing massively. What do you do?

Obviously, the first priority is to keep the airplane under control. This will take considerable force on the rudder and ailerons. You want to keep the nose pointed right down the runway. Then, as you reach Vr, you rotate to 10 degrees pitch, which should give you a speed close to V2. By this time, the offending engine should have auto-feathered its propeller so you don't have so much drag on that side, and the remaining engine will "uptrim" to give you 10% more torque. Once the airplane is positively airborne, the pilot not flying retracts the landing gear, and the pilot flying adjusts pitch to maintain V2. You don't run any checklists yet, you just concentrate on keeping the airplane under control and climbing to acceleration height (usually 1000' above airport elevation).

Each runway we use has a "turn procedure" assigned, to be used in the event of an engine failure. Many of these are rather simple and do not require a turn below acceleration height. Where obstacles present problems to slowly climbing aircraft, however, a complex turn procedure may be established. Most have textual descriptions, although a few are complex enough to require their own Jeppesen chart. Here's the turn procedure for runway 10L at Portland: "Climb via PDX radial 085 until reaching PDX DME 7.8, or IVDG DME 7.6, then turn right heading 280. Acceleration height 1030'." In this case, you'd make the turn to intercept the PDX 085 radial at 50 feet (!).

Upon reaching acceleration height, you level out, retract the flaps at V2 + 10 kts, and accelerate to Vse before resuming the climb at that airspeed. Only then does the pilot flying call for the engine failure checklist. This emergency checklist leads to several others ("engine failure cleanup items" and "single engine approach and landing"), which you'll do in between talking to ATC and your dispatcher (and possibly maintenance control), coordinating the arrival with your flight attendants, and perhaps making a PA to the passengers. Then it's time to land, smile at the passengers as they deplane, and go drink some beer.

Tuesday, May 09, 2006

Priorities

I hate to say it, but how much I like each of our layovers is in large part tied to the availability of free internet access. Most of the layover hotels that Megawhacker crews stay at now offer free Ethernet or WiFi access, although the quality of the wifi varies rather widely. A few holdouts don't offer any access, or charge for it, forcing me to (gasp) go out and do something that's not computer related.

Of course, in Reno the only thing to do near our hotel (The Nugget) is gamble, which is probably why they charge $13/day for wifi: they want people down in their casino. But my pay grade isn't quite high enough to incline me to gamble my paycheck away...so what to do? Fortunately, down the street there are a few businesses that offer free Wifi. There's "A. Paris Café," where I'm having breakfast now, or "O'sky's Pub," where you can check your email over a Guinness so long as you can ignore the shouting drunken rednecks manning to pool tables. Either option is far preferable to wasting time in your room at The Nugget (featuring 1970's decor and furniture).

Ooh. My mixed berry crêpes just came. Bon appétit!

Of course, in Reno the only thing to do near our hotel (The Nugget) is gamble, which is probably why they charge $13/day for wifi: they want people down in their casino. But my pay grade isn't quite high enough to incline me to gamble my paycheck away...so what to do? Fortunately, down the street there are a few businesses that offer free Wifi. There's "A. Paris Café," where I'm having breakfast now, or "O'sky's Pub," where you can check your email over a Guinness so long as you can ignore the shouting drunken rednecks manning to pool tables. Either option is far preferable to wasting time in your room at The Nugget (featuring 1970's decor and furniture).

Ooh. My mixed berry crêpes just came. Bon appétit!

Monday, May 08, 2006

Jimmy Hoffa Lives!

Well, this has me just about mad enough to spit. The most recent issue of Teamster magazine has a proud article ("All Systems Go," May 2006, condensed version here) about GoJet pilots certifying the Teamsters as their union. Not only are the Teamsters willing to sacrifice every principle that unionism holds dear for some extra dues money, but they'll gleefully brag about it, too. I'm embarrassed to say I'm a Teamster.

For those who aren't familiar, GoJet was an alter-ego airline started by Trans States Airlines owner Hulas Kanodia to circumvent the contract in place at TSA, which is represented by ALPA. The Trans States pilots protested strongly and filed a grievance with the National Mediation Board. The NMB ended up siding with Kanodia, but the real surprise was one of the petitions filed in support of the company: International Brotherhood of Teamsters, Airline Division. These are the same folks that represent pilots at my airline. Nevermind that GoJet and airlines like it are a direct threat to the security of regional pilots everywhere - the IBT saw an opportunity to poach some dues money. Jimmy Hoffa Sr. lives on through the culture of corruption that pervades the Teamsters. No wonder these scumbags left the AFL-CIO, they'd have been kicked out over this.

I'm writing this as someone who is generally pro-union and is actively involved in the union at my airline. You can imagine what this does to those pilots that're already ambivalent about union membership. I've had several fellow pilots tell me they'd like to stop paying dues over this. The IBT Airline Division has undermined unity at our pilot group at the time we need it the most: contract negotiations.

My beef is with the IBT Airline Division, not the union leadership at my airline. Our ExCo recognizes what a threat alter-ego airlines pose to us, and sent the airline division a strongly worded letter expressing our grave dissapointment. Unfortunately, that's about all we can do short of decertifying the crooks. I still support my local leadership 100% and will continue to help out. But in the meantime I've peeled the IBT sticker off my flight bag. I'm too embarassed to be publicly associated with that outfit.

For those who aren't familiar, GoJet was an alter-ego airline started by Trans States Airlines owner Hulas Kanodia to circumvent the contract in place at TSA, which is represented by ALPA. The Trans States pilots protested strongly and filed a grievance with the National Mediation Board. The NMB ended up siding with Kanodia, but the real surprise was one of the petitions filed in support of the company: International Brotherhood of Teamsters, Airline Division. These are the same folks that represent pilots at my airline. Nevermind that GoJet and airlines like it are a direct threat to the security of regional pilots everywhere - the IBT saw an opportunity to poach some dues money. Jimmy Hoffa Sr. lives on through the culture of corruption that pervades the Teamsters. No wonder these scumbags left the AFL-CIO, they'd have been kicked out over this.

I'm writing this as someone who is generally pro-union and is actively involved in the union at my airline. You can imagine what this does to those pilots that're already ambivalent about union membership. I've had several fellow pilots tell me they'd like to stop paying dues over this. The IBT Airline Division has undermined unity at our pilot group at the time we need it the most: contract negotiations.

My beef is with the IBT Airline Division, not the union leadership at my airline. Our ExCo recognizes what a threat alter-ego airlines pose to us, and sent the airline division a strongly worded letter expressing our grave dissapointment. Unfortunately, that's about all we can do short of decertifying the crooks. I still support my local leadership 100% and will continue to help out. But in the meantime I've peeled the IBT sticker off my flight bag. I'm too embarassed to be publicly associated with that outfit.

Sunday, May 07, 2006

The Future Is (almost) Here!

I've always been a bit of a computer geek. Ok, sometimes more than a bit, particularly when I can combine computers with aviation. I had several hundred instrument hours in MSFS 4.0 before I ever touched a real airplane. When I was 15, I coded a complete flight planning program (with great circle calculator!) in BASIC. And today I have an aviation centered blog. Yeah, I'll say no more.

But given that background, I feel fortunate to fly for an airline that is very technologically advanced, in the airplane that's usually the first to get the goodies. As I've written before, our entire fleet is equipped with Heads Up Guidance displays which allow us to shoot Cat III approaches and land in as little as 600 feet of visibility. We are the only regional airline in the United States to have this capability. In fact, we are the only airline of any size to have single-engine Cat III approval. The testing process to gain that FAA approval was extremely rigorous: our tech pilots shot thousands of approaches, often with one engine feathered, in the windiest conditions they could find, to a blind zero-zero touchdown...in the real airplane as well as the simulator. How did they make sure it was truly a blind landing in the airplane? Simple: leave the pilot-side window shade in place!

We also have dual Flight Management System computers installed, which allow us to use GPS satellites for departure, enroute, arrival, and approach navigation. GPS approach capability is widespread among light aircraft, but not at the airlines. A further development of the FMS approach will be the RNP approach. It is essentially a more precise GPS approach that allows for neat things like variable descent angles and curving approach paths - for all the details, see this recent post by John at Freight Dog Tales. RNP is in use at our sister airline, and approval is coming for us. Like the single-engine Cat III approval, getting the FAA to okay RNP has involved our tech pilots demonstrating thousands of approaches in very adverse conditions.

Our newest up-and-coming toy is coming mainly because of the Megawhacker's wholly inadequate radar system. My airline asked the aircraft manufacturer to install a better radar; they replied that they'd be happy to, for around $1 million. Management decided that for that price tag, they could get something a whole lot better. Initially the search was just for a satellite weather datalink, but the result is that we're now getting a full-blown Electronic Flight Bag (EFB).

The basic conception of an EFB is of a laptop computer that electronically stores all the charts and manuals you'd normally lug around in your flight case. This isn't new; jetBlue has been doing this since their inception five years ago. The new EFBs are much more than that. They are now custom designed computers, often permanently mounted tablet PCs, running Windows-based proprietary software. The newest concept, the one that my airline is pursuing, is to use a satellite link to provide real-time weather (text, charts, nexrad) on the EFB, which will also receive navigational data from the FMS units. This allows for moving map options that can display flight plan routing against overlays such as radar returns, lightning strikes, reported turbulence, winds aloft, etc.

That's the very basic system, the one the company is pursuing in the very short term. What's really neat is all the additional capability this hardware can provide with some extra software and little else. The satellite link allows not only weather downloading, but two way text and voice communication. Most airlines already have this capability, but it's a rather hodgepodge system that involves lots of acronyms (ACARS, SELCAL, AIRINC) and some significant geographical limitations. The satellite link will allow for nearly worldwide communications capability, and adding a computer to the mix will automate the process. The idea is to be able to quickly and painlessly talk to dispatch or maintenance control or even aircraft or medical specialists at the touch of a button. The pilots aren't the only ones to get in on the fun: the flight attendants will have their own EFB unit, through which they will eventually be able to do everything from reordering supplies from Food & Beverage to forwarding Special Passenger requests to completing the passenger count form and zapping the data via secure wifi to the captain's EFB. Someday we may see the rampers punching in cargo numbers on their own wifi-enabled PDA, with the EFB generating all weight & balance and performance data with no pilot input.

Oh yeah, one more thing: no more updating charts. Filing the Jeppesen revisions every two weeks has been a reviled chore since time immortal. With all charts and manuals onboard the EFB, however, revising them will simply involve tech pubs sending the new files via datalink.

Some of this is probably far in the future, but I don't doubt that it'll happen. Once the basic hardware is installed, additional capabilities only increase the return on investment. The biggest obstacle, in my opinion, will be the Luddite faction of the FAA. One thing is for sure, though: we're definately getting the weather link, and soon. That alone will be a huge improvement in safety and efficiency.

But given that background, I feel fortunate to fly for an airline that is very technologically advanced, in the airplane that's usually the first to get the goodies. As I've written before, our entire fleet is equipped with Heads Up Guidance displays which allow us to shoot Cat III approaches and land in as little as 600 feet of visibility. We are the only regional airline in the United States to have this capability. In fact, we are the only airline of any size to have single-engine Cat III approval. The testing process to gain that FAA approval was extremely rigorous: our tech pilots shot thousands of approaches, often with one engine feathered, in the windiest conditions they could find, to a blind zero-zero touchdown...in the real airplane as well as the simulator. How did they make sure it was truly a blind landing in the airplane? Simple: leave the pilot-side window shade in place!

We also have dual Flight Management System computers installed, which allow us to use GPS satellites for departure, enroute, arrival, and approach navigation. GPS approach capability is widespread among light aircraft, but not at the airlines. A further development of the FMS approach will be the RNP approach. It is essentially a more precise GPS approach that allows for neat things like variable descent angles and curving approach paths - for all the details, see this recent post by John at Freight Dog Tales. RNP is in use at our sister airline, and approval is coming for us. Like the single-engine Cat III approval, getting the FAA to okay RNP has involved our tech pilots demonstrating thousands of approaches in very adverse conditions.

Our newest up-and-coming toy is coming mainly because of the Megawhacker's wholly inadequate radar system. My airline asked the aircraft manufacturer to install a better radar; they replied that they'd be happy to, for around $1 million. Management decided that for that price tag, they could get something a whole lot better. Initially the search was just for a satellite weather datalink, but the result is that we're now getting a full-blown Electronic Flight Bag (EFB).

The basic conception of an EFB is of a laptop computer that electronically stores all the charts and manuals you'd normally lug around in your flight case. This isn't new; jetBlue has been doing this since their inception five years ago. The new EFBs are much more than that. They are now custom designed computers, often permanently mounted tablet PCs, running Windows-based proprietary software. The newest concept, the one that my airline is pursuing, is to use a satellite link to provide real-time weather (text, charts, nexrad) on the EFB, which will also receive navigational data from the FMS units. This allows for moving map options that can display flight plan routing against overlays such as radar returns, lightning strikes, reported turbulence, winds aloft, etc.

That's the very basic system, the one the company is pursuing in the very short term. What's really neat is all the additional capability this hardware can provide with some extra software and little else. The satellite link allows not only weather downloading, but two way text and voice communication. Most airlines already have this capability, but it's a rather hodgepodge system that involves lots of acronyms (ACARS, SELCAL, AIRINC) and some significant geographical limitations. The satellite link will allow for nearly worldwide communications capability, and adding a computer to the mix will automate the process. The idea is to be able to quickly and painlessly talk to dispatch or maintenance control or even aircraft or medical specialists at the touch of a button. The pilots aren't the only ones to get in on the fun: the flight attendants will have their own EFB unit, through which they will eventually be able to do everything from reordering supplies from Food & Beverage to forwarding Special Passenger requests to completing the passenger count form and zapping the data via secure wifi to the captain's EFB. Someday we may see the rampers punching in cargo numbers on their own wifi-enabled PDA, with the EFB generating all weight & balance and performance data with no pilot input.

Oh yeah, one more thing: no more updating charts. Filing the Jeppesen revisions every two weeks has been a reviled chore since time immortal. With all charts and manuals onboard the EFB, however, revising them will simply involve tech pubs sending the new files via datalink.

Some of this is probably far in the future, but I don't doubt that it'll happen. Once the basic hardware is installed, additional capabilities only increase the return on investment. The biggest obstacle, in my opinion, will be the Luddite faction of the FAA. One thing is for sure, though: we're definately getting the weather link, and soon. That alone will be a huge improvement in safety and efficiency.

Saturday, May 06, 2006

Off the Radar, In the Spotlight

I think that most of my readers are also regular visitors at Cockpit Conversation; if you're not, do yourself a favor and read the last month or so of posts. Aviatrix has a new job as a charter pilot wayyy up north in a remote section of Canada, and it's really fascinating reading. The area she is in is very "off the radar," so to speak, so her observations as a newcomer to living and flying in that environment are quite interesting to those of us not normally exposed to it.

Prospective commercial pilots are often lured to an aviation career with the promise of beauty, adventure, challenge, camaraderie, and travel to the interesting parts of our world. To be sure, aviation still offers all this - but it's not really at that coveted airline job. The most interesting stories about interesting people and airplanes involve jobs most people have never heard of - sometimes in your backyard, sometimes in obscure corners of the globe. Some of these pilots are just passing through, working their way to "bigger and better." A few have already been there and decided it wasn't for them. Many have known no other lifestyle and do not wish to.

To be sure, airline flying has its advantages, not the least of which are safety and comfort. Aviatrix has some tough flying and harsh living ahead of her at this new job. But she'll experience all that aviation has to offer far more vividly than she will when she gets to Air Canada or WestJet. We're all fortunate to be able to ride along with her.

So get to Cockpit Conversation for the current best of the aviation blogosphere. You don't really want to read about my boring old "before start" flows, anyway!

Prospective commercial pilots are often lured to an aviation career with the promise of beauty, adventure, challenge, camaraderie, and travel to the interesting parts of our world. To be sure, aviation still offers all this - but it's not really at that coveted airline job. The most interesting stories about interesting people and airplanes involve jobs most people have never heard of - sometimes in your backyard, sometimes in obscure corners of the globe. Some of these pilots are just passing through, working their way to "bigger and better." A few have already been there and decided it wasn't for them. Many have known no other lifestyle and do not wish to.

To be sure, airline flying has its advantages, not the least of which are safety and comfort. Aviatrix has some tough flying and harsh living ahead of her at this new job. But she'll experience all that aviation has to offer far more vividly than she will when she gets to Air Canada or WestJet. We're all fortunate to be able to ride along with her.

So get to Cockpit Conversation for the current best of the aviation blogosphere. You don't really want to read about my boring old "before start" flows, anyway!

Six Leg Days

Because turboprop airliners tend to fly shorter legs than their turbojet brethern, they usually fly more legs per day. A 757 pilot at a major airline might fly one or two legs per day of their trip, a 737 or CRJ pilot perhaps two to four legs; but it's common for turboprop pilots to fly six to eight legs per day. Megawhacker pilots are lucky, because our average stage length is longer than most turboprops, so we don't have to fly as many legs. Still, some of our trips include a few days with six or seven legs.

While the regulations limit you to eight hours of flight time per day, they only limit duty time to 15 hours - even 16 hours in some cases. The company can schedule as little as 20 minutes between flights, or they may put in one or more "breaks" which can last up to several hours. Either way, at the end of a 6+ leg day, you're guaranteed to be tired.

So what all do I do between legs? After we shut down, I call in our "in times" to ops, and then do the parking checklist. I'll usually go in back to help the flight attendants cross seatbelts, pick up trash, and hokie the floor. After that I'll scrounge around the galley for some food or drink, or maybe make a food run inside the terminal. Once I'm back, I'll slide back into the right seat and launch into my "before start" flows.

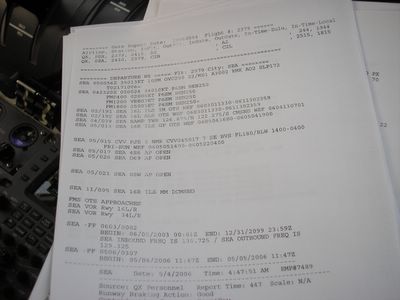

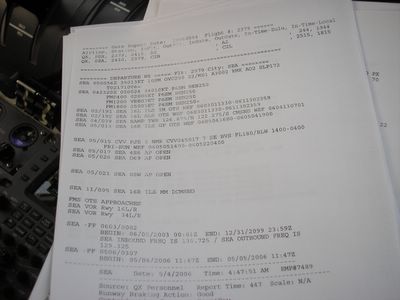

First, I review the dispatch release and the weather enroute and at our destination. I verify that any alternate requirements are met, and that the fuel burn numbers look correct. If there's anything of note, I'll mention it to the captain.

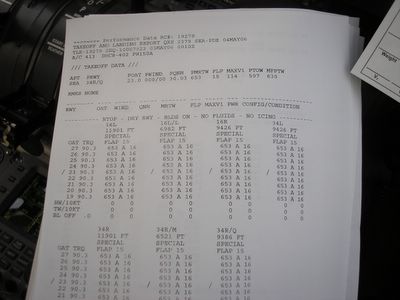

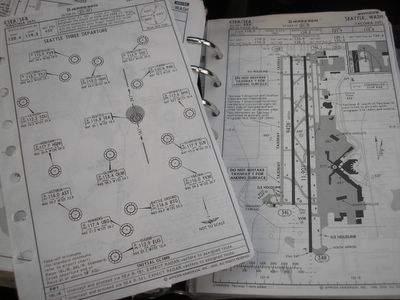

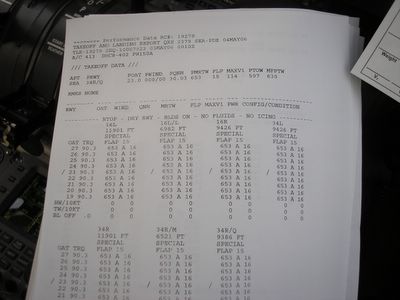

Next, I listen to the current ATIS, copy our IFR clearance, and pull out the neccessary charts for departure. I look up our takeoff performance numbers and airport-specific engine failure procedures. All this is copied onto a takeoff data card. Again, if there's anything out of the ordinary, I'll run it by the captain.

I set our landing altitude on the pressurization control panel...

...arm the emergency lights...

...and set up the AFCS (ie flight director/autopilot).

I set the altimeter and acceleration height on the PFD, and guess what we'll use for speed bugs.

I program the flight plan into the FMS, crossfill it to the captain's FMS, and input the preliminary fuel and weight numbers.

Finally, I set the ARCDUs for departure - ie, tune the radios.

After that's done, there's nothing to do but run the "Before Start" checklist, wait for the captain to give me weight & balance numbers, put them into the FMS, and get my seatbelt on. Then it's onto the next leg...repeat as neccessary.

Update: Hmm, re-reading that, it sounds like I'm complaining about my excessive workload between flights, or the fact that the company schedules six leg days. That's not it at all. I can whip out my before start flows in under five minutes, and a quick succession of short legs makes the day go quicker, since takeoff & approach & landing is far more interesting than cruise flight. Of course, with the Megawhacker replacing Miniwhacker flying in Seattle, I may get a lot more 6-8 leg days sooner rather than later!

While the regulations limit you to eight hours of flight time per day, they only limit duty time to 15 hours - even 16 hours in some cases. The company can schedule as little as 20 minutes between flights, or they may put in one or more "breaks" which can last up to several hours. Either way, at the end of a 6+ leg day, you're guaranteed to be tired.

So what all do I do between legs? After we shut down, I call in our "in times" to ops, and then do the parking checklist. I'll usually go in back to help the flight attendants cross seatbelts, pick up trash, and hokie the floor. After that I'll scrounge around the galley for some food or drink, or maybe make a food run inside the terminal. Once I'm back, I'll slide back into the right seat and launch into my "before start" flows.

First, I review the dispatch release and the weather enroute and at our destination. I verify that any alternate requirements are met, and that the fuel burn numbers look correct. If there's anything of note, I'll mention it to the captain.

Next, I listen to the current ATIS, copy our IFR clearance, and pull out the neccessary charts for departure. I look up our takeoff performance numbers and airport-specific engine failure procedures. All this is copied onto a takeoff data card. Again, if there's anything out of the ordinary, I'll run it by the captain.

I set our landing altitude on the pressurization control panel...

...arm the emergency lights...

...and set up the AFCS (ie flight director/autopilot).

I set the altimeter and acceleration height on the PFD, and guess what we'll use for speed bugs.

I program the flight plan into the FMS, crossfill it to the captain's FMS, and input the preliminary fuel and weight numbers.

Finally, I set the ARCDUs for departure - ie, tune the radios.

After that's done, there's nothing to do but run the "Before Start" checklist, wait for the captain to give me weight & balance numbers, put them into the FMS, and get my seatbelt on. Then it's onto the next leg...repeat as neccessary.

Update: Hmm, re-reading that, it sounds like I'm complaining about my excessive workload between flights, or the fact that the company schedules six leg days. That's not it at all. I can whip out my before start flows in under five minutes, and a quick succession of short legs makes the day go quicker, since takeoff & approach & landing is far more interesting than cruise flight. Of course, with the Megawhacker replacing Miniwhacker flying in Seattle, I may get a lot more 6-8 leg days sooner rather than later!

Tuesday, May 02, 2006

Subscribe to:

Comments (Atom)